More Information...

Cryogenic Facilities A

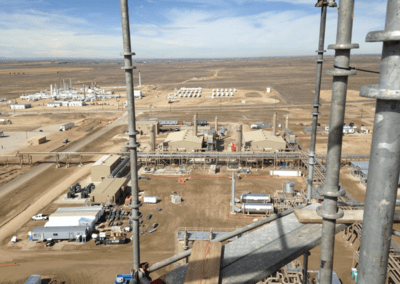

Project Name: Lancaster

Client: Anadarko (OXY)

Location: Denver Colorado

Timeline: 2018

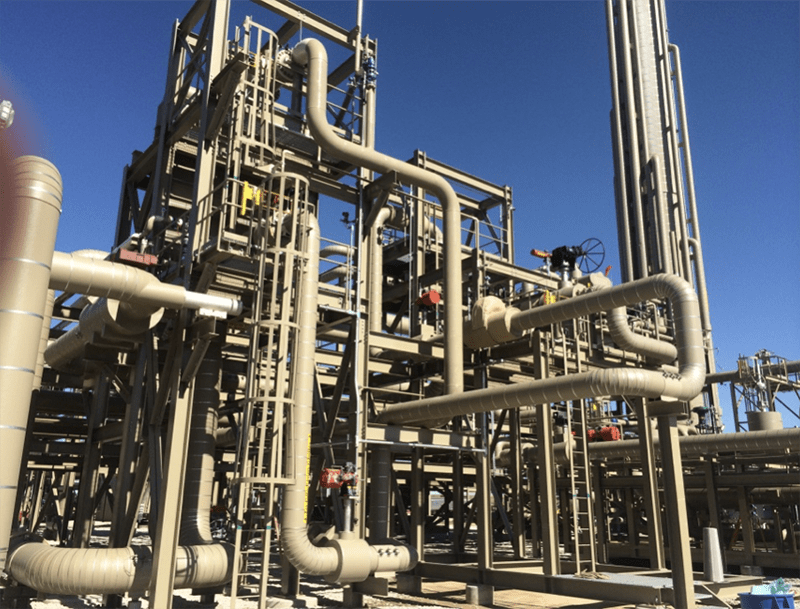

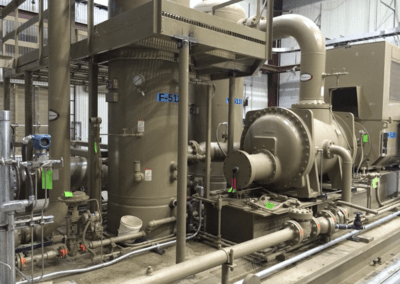

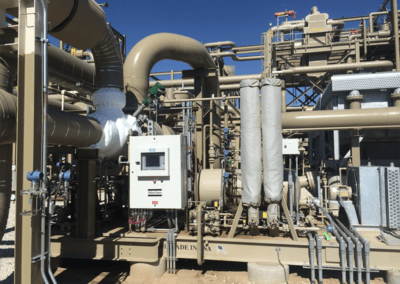

Lancaster 300MMSCFD CRYO Facility

Project Summary:

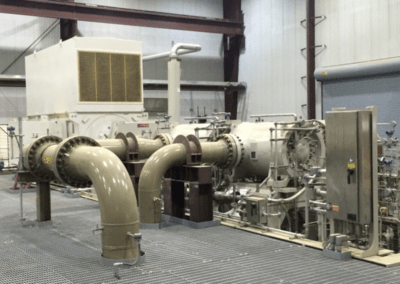

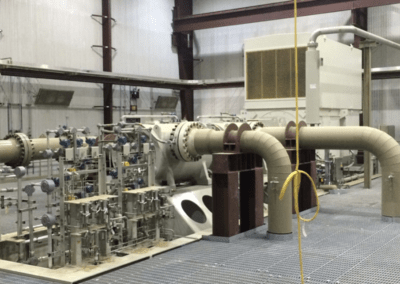

Lancaster is a cryogenic deep -cut gas processing facility that is comprised of two trains. Train 1 is designed to meet a capacity of 150MMSCFD and train 2 is designed to meet a capacity of 150MMSCFD.

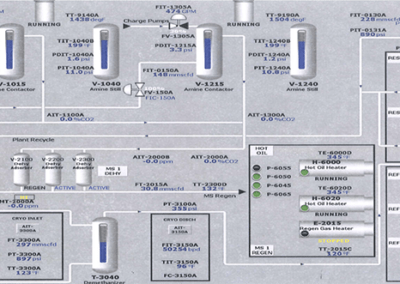

It took a team of 6 GRD field technician 3 months to commission and start-up train 1 and 2.5 months to commission and start-up train 2. As part of the commissioning process, GRD field technician calibrated and sign-off over 3000 I/O points.

Roles and Responsibilities:

- Reviews engineering documents to ensure that all commissioning & start-up requirements are accounted for in the design

- Prepares and keeps up to date the pre-commissioning and commissioning execution plans (including the schedule and the mobilization of personnel and equipment)

- Develops the schedule and associated costs for all commissioning and start activities with the project management team and project controls group

- Develops and oversees the preparation of the procedures required to prepare the facilities for commissioning of all processing and utility equipment

- Responsible for ensuring commissioning and start-up procedures are communicated with the operations team

- Preparation of the performance test procedures and of the operating manuals with the engineering and operations team

- Coordinates between Operations and Project teams for the handover of the equipment as per applicable client standards/specifications requirements

- Engages commissioning vendors as required

- Prepares and submit commissioning progress reports to the project management and to the commissioning department

- Assists in the preparation and management of the close-out process, providing reports to implement continuous improvement opportunities from lessons learned

Canadian Head Office - Calgary

Calgary AB, Canada

T2P 3E7

US Head Office - Denver, CO

Suite 600H, 1630 Welton Street

Denver, CO

80202

US Field Office - Gillette, WY

413 South Gillette Avenue

Gillette, WY

82716

Get in Touch Using our Contact Form Below

or call Now: